Extracting lotus fiber micro-optic fibers with diameters ranging from 3μm to 5μm from lotus slices with a diameter of about 8cm is not about creating an exquisite dish, but a new achievement in nano-optics by the team of Professor Li Baojun and Associate Professor Yang Xianguang's research group at Jinan University.

These lotus fiber micro-optic fibers possess the characteristics of high biocompatibility and extremely low active waveguide loss, capable of achieving passive waveguides within the visible light range. At the same time, due to the small diameter of the fiber and its flexible micro-fiber characteristics, it can be used for biosensing applications in extremely small detection areas.

Advertisement

Not only can it exhibit its inherent fluorescence effect, but it can also achieve the waveguide effect of coupled light. These unique properties make the single-fiber monitor an excellent component with multiple sensing functions, which can be used for pH value detection and bacterial activity testing.

At the same time, these characteristics also make a positive contribution to the development of environmentally friendly multiplex biosensing technology.

In terms of its application prospects:Firstly, it can promote the development of biosensing technology.

By leveraging the good biocompatibility and flexibility of lotus root silk microfibers, single-filament sensors are expected to become an important component in the field of biosensing.

When used inside biological bodies, they can monitor physiological indicators such as pH value under different environmental conditions, thus providing a new approach for medical diagnosis and health monitoring.

Secondly, it can be used for environmental monitoring and pollution detection.

The characteristics of single-filament sensors make them suitable for monitoring various pollutants in the environment, such as bacterial activity detection. This is of great significance for environmental monitoring and water quality safety, helping to detect and deal with potential environmental issues at an early stage.Thirdly, it can promote the innovation of optical devices.

The waveguide characteristics of lotus root silk microfibers bring new possibilities to optical devices, including assisting in the development of new types of optical sensors, waveguide modulators, etc., and then applying them to communication, imaging, and other optical application fields.

Fourthly, it can be used in biomedical engineering.

Using the flexible microfibers of lotus root silk microfibers, it is expected to create new implantable devices, thereby playing a role in tissue engineering and drug delivery.

At the same time, the lotus root silk microfibers extracted this time have a uniform diameter, smooth surface, almost no optical defects, and show obvious red, green, and blue fluorescence under different wavelengths of laser irradiation, and exhibit stable fluorescence intensity.This fluorescent signal can be transmitted along the axial direction of the lotus root microfiber, achieving transmission characteristics similar to those of communication optical fibers. In addition, the lotus root microfiber has good flexibility and can be bent into different shapes, which can be used to integrate micro-nano optical devices. The long-term goal of Yang Xianguang's research team is to use lotus root optical sensors for human gastric juice samples. To this end, it is necessary to accurately simulate the gastric juice environment, including not only detecting the liquid environment of gastric juice, but also monitoring the changes of Helicobacter pylori in gastric juice. To achieve this goal, they intend to obtain active waveguide and passive waveguide optical signals in the simulated gastric juice microenvironment at the same time, so as to realize bio-friendly, simple and convenient medical monitoring of human gastric juice samples. Why choose a lotus root for scientific research topic?So, what reasons did Yang Xianguang base his topic on a lotus root slice? He stated that in modern biophysics and biomedicine, it is very important to continuously monitor the physiological and pathological states of living organisms.

Even minor fluctuations above the baseline parameters may be signals of biological changes or functional changes in cellular responses.

To address the study and diagnosis of biological environments, micro/nano optical biosensors have become powerful tools.

Optical biosensors based on micro/nano optical fibers indeed have high value in detecting and monitoring liquid environments and biological activities.

However, most traditional optical fibers are still based on glass, semiconductor, or metal materials, which are not entirely suitable for biological-related environments and are prone to physical damage such as bending, flexing, or compression.Currently, the traditional optical fiber materials used in biosensors have a loss level of 0.1dB/μm, which presents a problem of high loss.

Moreover, when in contact with biological samples, due to poor biocompatibility, traditional optical fibers are prone to adversely affect the samples. At the same time, signals are susceptible to cross-interference, resulting in low sensitivity.

However, a natural material like lotus root slices can just solve the aforementioned problems. However, how to accurately separate single microfibers from the lotus root silk fiber bundle is the first challenge facing the research team.

The lotus root silk fiber bundle is wrapped by components such as pectin, not only arranged neatly, but also in a spiral structure, which makes obtaining single microfibers not only need to remove components such as pectin, but also to unspiral and accurately extract the target fiber.

And unspiraling at the micro-nano scale is even more difficult. However, the team first studied the lotus root silk for two years, and then after three months of unremitting efforts, successfully explored an innovative method of chemical-assisted physical separation, and finally obtained single microfibers with uniform diameter, smooth surface, and considerable length.Specifically, they managed to free every two single micro-fibres within the lotus root silk fiber bundles by repeatedly using strong alkaline solutions and deionized water.

Next, with the help of two melt-drawn conical optical fibers and double-sided adhesive tape, they cleverly straightened the fiber bundles and fixed them at both ends with the tape.

Then, they slowly interspersed the conical optical fibers between the lotus root silk bundles and applied a transverse force using the thicker part of the conical optical fiber.

Subsequently, with the aid of an optical fiber adjustment frame, they precisely controlled the direction and magnitude of the transverse force, ultimately obtaining the desired single micro-fibers.

At this point, they soaked the extracted lotus root silk bundles in a sodium hydroxide aqueous solution with a mass concentration of 20g/L for two hours, then used the optical fiber to transfer the lotus root silk onto a clean glass slide, and repeatedly added deionized water six times to remove any residual sodium hydroxide solution.Utilizing an optical fiber adjustment frame with a precision of 50 nanometers, the lotus root silk micro-fiber is separated, which at this point has a spiral structure.

Subsequently, the morphology of the lotus root silk micro-fiber is characterized. First, the lotus root silk micro-fiber is transferred to a clean silicon wafer and dried in an oven at a temperature of 25°C for 30 minutes.

Then, the scanning electron microscope is turned on and the voltage is adjusted to 20KV. At this time, secondary electron emission is used to observe the microstructure of the lotus root silk micro-fiber under a high vacuum environment with a 3.5K magnification, thereby obtaining the micro surface structure of the lotus root silk micro-fiber.

Under the microscope, the lotus root silk micro-fiber presents a one-dimensional cylindrical structure, with a length greater than 600μm and a diameter of 3μm-5μm. It is not only uniform in diameter but also smooth in surface and has very few optical defects.

After that, they began to study the passive and active waveguide properties of the lotus root silk micro-fiber. At different positions, the research team used optical fibers to couple red, green, and blue laser beams into the lotus root silk micro-fiber for transmission.Due to the refractive index of lotus root silk microfibers being much greater than that of air, this design can effectively reduce the scattering loss of light during the transmission process in the lotus root silk microfibers.

By doing so, they successfully detected the intensity of passive optical signals at different transmission distances at the end of the lotus root silk microfibers, achieving optical transmission of passive waveguides.

Then, they once again used optical fibers to couple blue light into the lotus root silk microfibers. Due to the photoluminescence process, the lotus root silk microfibers would emit green fluorescence. And the fluorescence signal would propagate along the length direction of the lotus root silk microfibers to different distances.

After being processed by the microscope spectrophotometer's objective, filter, slit, and grating, the light with spectral information can reach the detector and complete spectral acquisition.

This can achieve optical transmission of active waveguides and also provides key data for further research on the characteristics of optical waveguides.Design of Bacterial Sensors and pH Sensors Based on Lotus Root Fiber Micro-Optical Fibers

In conclusion, leveraging the passive and active waveguide properties of lotus root fiber micro-optic fibers, the team demonstrated two applications.

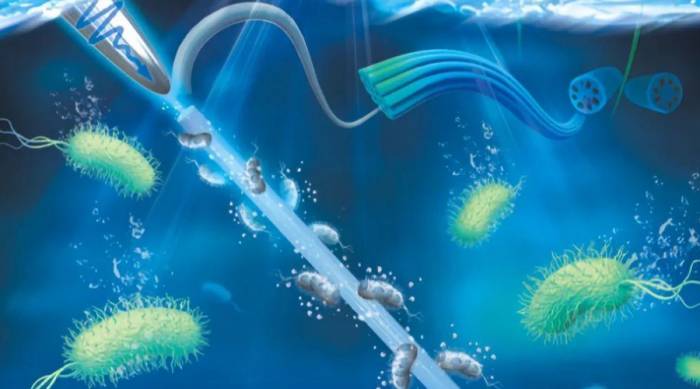

Firstly, based on the passive waveguide characteristics of the lotus root fiber micro-optic fibers, the research group designed a bacterial sensor.

During the process of bacterial and cellular apoptosis, the change in the permeability of the bacterial cell membrane leads to the gradual release of enzymatic substances from inside the bacterial cells into the surrounding liquid microenvironment.Within the liquid microenvironment, enzymatic substances can interact with the hydroxyl groups on the surface of lotus root fiber cellulose through the active sites of enzymes, thereby adhering to the surface of the lotus root fiber micro-optic fiber.

The enzymatic substances will be captured by the lotus root fiber micro-optic fiber, which can change the surface roughness and thickness of the lotus root fiber micro-optic fiber. At this time, the optical signal power detected by the collection end will also change.

Secondly, based on the active waveguide characteristics of the lotus root fiber micro-optic fiber, the research group designed a pH sensor.

By changing the pH value of the solution, the fluorescence intensity of the lotus root fiber micro-optic fiber can be reversibly changed.

The principle is that the main component of lotus root fiber is cellulose, and the increase of cations in an acidic environment will cause charge repulsion, which inhibits the non-radiative transition in the interaction between cellulose nanocluster molecules, thereby enhancing its fluorescence intensity.In an alkaline environment, the intermolecular interactions within cellulose nanoclusters are weakened, leading to a decrease in fluorescence intensity.

So far, the preparation and application of lotus root silk microfibers have been completed. Eventually, the related paper was published in Nano Letters with the title "Light-Emitting Microfibers from Lotus Root for Eco-Friendly Optical Waveguides and Biosensing," with Yang Xianguang as the first author and corresponding author.

Comments