It is understood that traditional thin-film deposition techniques usually require high temperatures when preparing crystalline thin films, which may pose thermal instability issues for flexible substrates and other device components, thus limiting their application in large-scale, low-cost optoelectronic applications.

Therefore, the team from City University of Hong Kong proposed the use of a low-temperature pulse irradiation synthesis method, which reduces the synthesis temperature through a self-ignition combustion process, achieving the goal of preparing metal sulfide thin films on flexible substrates.

In the initial literature review, they found that the thin films and synthesis of various metal sulfides often involve high-temperature crystallization processes, and also noticed that the high-temperature treatment in existing technologies is not suitable for flexible substrates.

Advertisement

After identifying the problem, the research group designed several possible experimental schemes, and finally developed a pulse irradiation synthesis strategy, and ensured the efficiency of this method in synthesizing metal sulfide thin films at low temperatures through continuous experiments and optimization.

This involves controlling energy pulses, adjusting irradiation and temperature curves, and optimizing the structure of the reactant layers, among other aspects.After optimizing the synthetic parameters, they carried out a series of experiments to verify their effectiveness. Photothermal electrical devices were successfully synthesized on various polymer substrates, and their photoelectric response performance was tested.

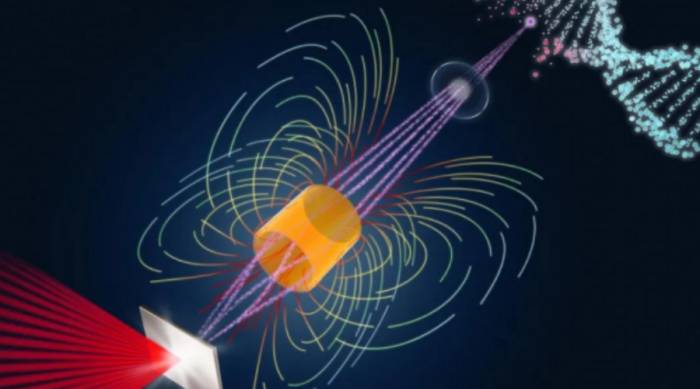

At the same time, the research team used various analytical techniques, such as grazing incidence wide-angle X-ray scattering and transmission electron microscopy, to determine the crystallinity and grain orientation of the thin film during pulse irradiation synthesis.

Simultaneously, they used methods such as simulation and emulation to evaluate the thin film's performance in photothermal electric (PTE) properties.

In explaining the photoelectric response of the metal sulfide thin film, the team believes that the film's response to near-infrared light is due to the material's relatively narrow bandgap.

During repeated tests, they accidentally found that the position of the laser irradiation in the device and the type of flexible substrate have a significant impact on the photoelectric response.Based on the findings, they conducted further research and reviewed relevant literature, ultimately proposing the photothermal electromechanical mechanism of thermoelectric thin films, as well as the thermal coupling effect between the thin film and the substrate.

Overall, this method successfully avoided the high-temperature processing steps required in traditional techniques, overcoming the limitations on thermally unstable substrates and device components.

By achieving an ultra-short synthesis time in pulse irradiation synthesis, the research team reduced the synthesis temperature to 150°C, and the reaction could be completed within one second, which was an unprecedented low-temperature and efficient synthesis. This innovation provides a new approach for preparing high-quality metal sulfide thin films on flexible substrates.

In addition, due to the low temperature of the synthesis process, this method allows most organic flexible substrates to retain their original mechanical properties, making it possible to synthesize various metal sulfide thin films on a variety of flexible substrates.

At the same time, the research team deeply explored the thermal coupling effect between the polymer substrate and the metal sulfide thin film, improving the photothermal electromechanical performance through substrate-related thermal management.Through their research, they realized that the thermal diffusion rates of different substrates and their temperature distribution under local laser irradiation of the device affected the output photovoltage.

This discovery provides a new strategy for designing photothermal electrical devices, and by choosing the appropriate flexible substrate, the device performance can be better controlled.

In addition, while solving the problem of low-temperature synthesis of metal sulfides, the team also discovered the intrinsic connection between the extremely low thermal properties of materials and the photothermal electrical response of the device.

While discovering new knowledge, by proposing and verifying new synthesis methods and material thermal management strategies, the team successfully solved the problem of contradiction between temperature and performance when preparing metal sulfide thin films on flexible substrates.

Recently, the related paper was published in Nature Communications with the title "Pulse irradiation synthesis of metal chalcogenides on flexible substrates for enhanced photothermoelectric performance" [1].City University of Hong Kong Zhang Yuxuan is the first author, Dr. Meng You from City University of Hong Kong is the co-first author and co-corresponding author, and Associate Professor Huang Junxian and Professor He Songxian from City University of Hong Kong serve as co-corresponding authors.

The reviewer commented: "The authors have demonstrated a pulsed radiation method for synthesizing thermoelectric thin films, and the lower growth temperature requirement is very suitable for flexible optoelectronic devices, which can be synthesized directly on polymer substrates without denaturation."

In addition, the reviewer pointed out that the low thermal diffusivity of these polymer substrates helps to improve the PTE performance. They believe that this work is both interesting and comprehensive and should attract the attention of researchers in the fields of two-dimensional material synthesis, photodetectors, and thermoelectric materials.

With the unique properties of the photothermal effect, the detectors prepared on flexible substrates will have photoelectric responses in the near-infrared and even far-infrared, and are not limited by the bandgap of the material itself.

It is expected that this achievement will have a wide range of potential applications in the future, especially in the field of photothermoelectricity. The specific applications mainly include:Firstly, for flexible thermophotovoltaic detectors.

Due to the new approach provided by this study for fabricating metal sulfide thin films at low temperatures, flexible thermophotovoltaic detectors will be able to achieve higher performance on suitable flexible substrates. This can be applied to thermal imaging perception, such as in security monitoring, fire detection, military reconnaissance, and other fields.

Secondly, for communication technology.

The thermophotovoltaic effect provides the ability to convert light signals into electrical signals, thus having a wide range of application potential in the field of optical communication. This may promote the development of flexible thermophotovoltaic devices in high-speed communication, optical signal processing, and other areas.

Thirdly, for autonomous driving technology.Deploying flexible thermoelectric devices on vehicles can achieve more precise and sensitive environmental perception. This is crucial for enhancing the safety and reliability of autonomous driving vehicles.

Secondly, for medical diagnostics.

The wide-spectrum response and high sensitivity of thermoelectric devices make them potentially applicable in the field of medical imaging. They are expected to be used in medical equipment such as infrared optical imaging and body temperature detection, providing more options for medical diagnostics.

Thirdly, for energy collection and thermoelectric devices.

Metal sulfide thin films with thermoelectric properties have certain application potential in the field of thermoelectricity. The development of flexible thermoelectric devices may bring more efficient energy collection technology, which can be used in embedded electronic devices, wearable technology, etc.In light of the achievements of existing research, the research team will further optimize the pulsed radiation synthesis method, adjust synthesis parameters, to enhance the performance of metal sulfide thin films. This may include further reducing the synthesis temperature, shortening the reaction time, and optimizing the crystallinity and optoelectronic properties of the thin films.

Next is the expansion and diversity research of materials. Specifically, the team may explore a wider variety of metal sulfides to expand the scope of application of this method.

Not limited to Bi2Se3, Bi2Te3, and SnSe2, the research team may also study other thermoelectric materials with potential application value, thereby promoting the application of flexible thermophotovoltaic devices in different fields.

In addition, they will carry out work on device integration and application scenario verification, applying the synthesized metal sulfide thin films to actual flexible thermophotovoltaic devices, such as integrating and verifying in flexible sensors, flexible energy devices, and other aspects.

If this method can be proven to be feasible in large-scale production and industrial applications, the team may consider promoting it to industrialization, which may include technology transfer, patent applications, and cooperation with the industry.Support: Ren

Layout: He Chenlong, Xi Man

Comments